CFB Boilers (Circulating Fluidized Bed Boilers) Sumitomo Heavy

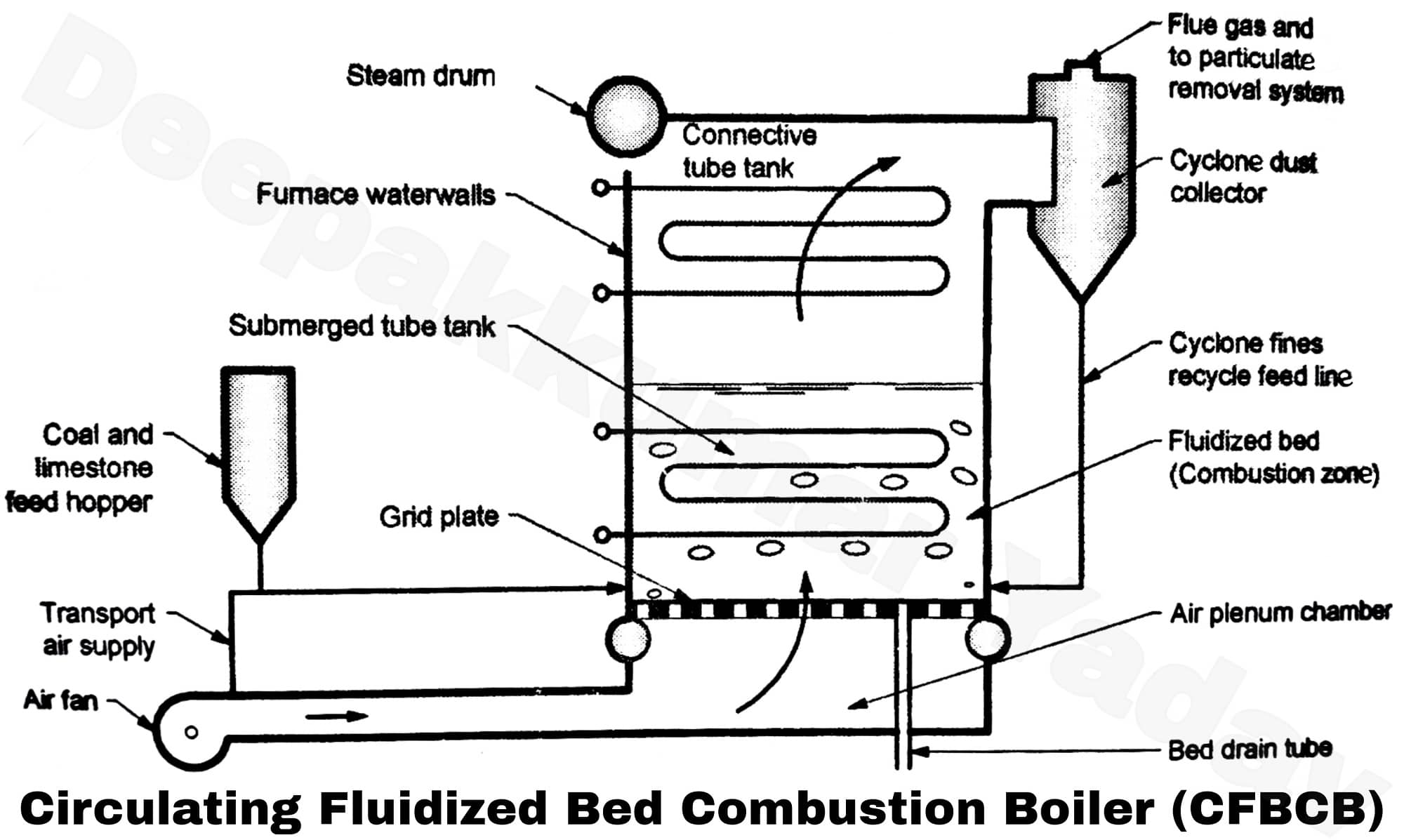

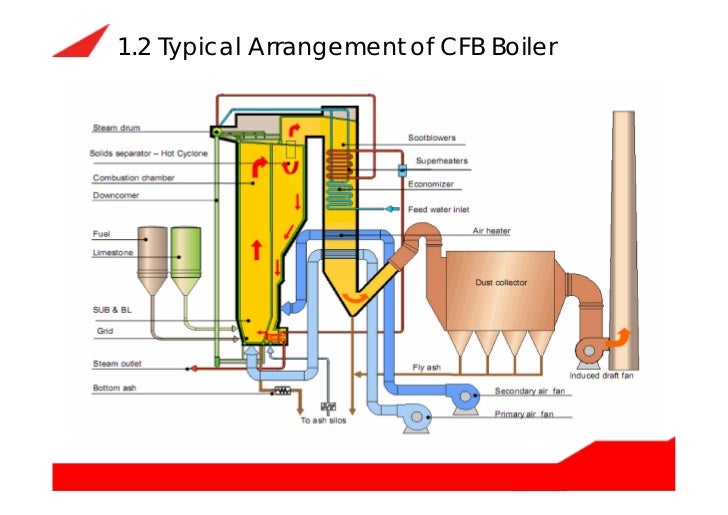

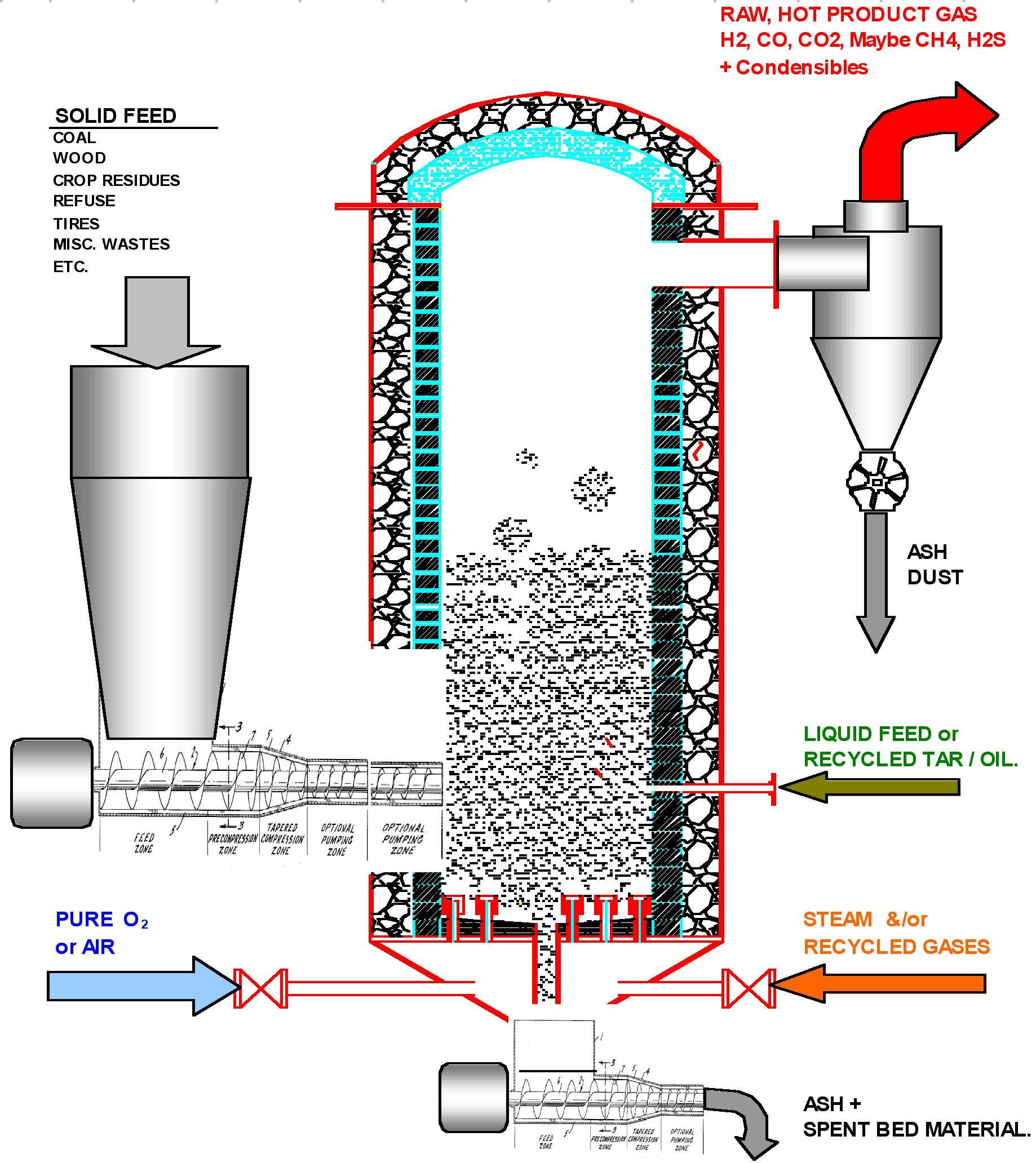

Circulation Fine particles of partly burned coal, ash and bed material are carried along with the flue gases to the upper areas of the furnace and then into a cyclone. In the cyclone the heavier particles separate from the gas and falls to the hopper of the cyclone. This returns to the furnace for recirculation.

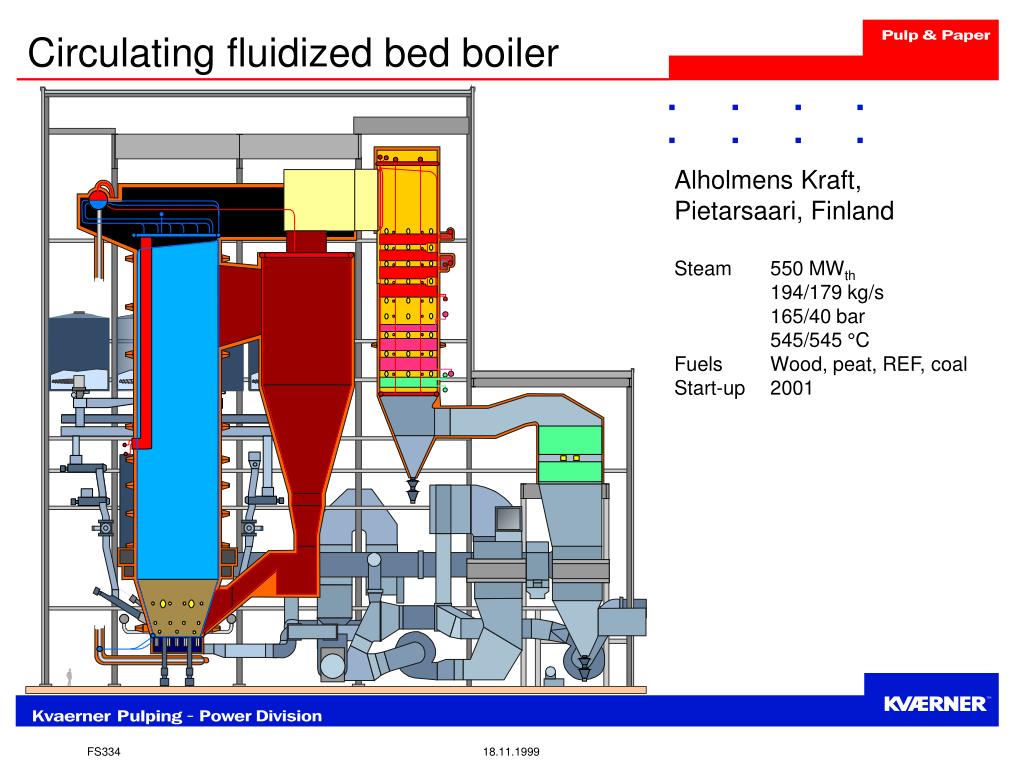

PPT Circulating fluidized bed boiler PowerPoint Presentation, free

Circulating fluidized bed combustion (CFBC) power generation technology has developed rapidly in the last 30 years, and is now fully commercial and available at sizes up to 600 MW.

Fluidized Bed Combustion Boilers (FBCB)

Fluidized-bed boilers are the most common type of boiler recommended for biomass fuel, which is burned within a hot bed of inert particles, typically sand. The fuel-particle mix is suspended by an upward flow of combustion air within the bed. As velocities increase the gas/solid mix exhibits fluid-like properties.

Circulating fluidized bed Boiler, MACHMALL

28-01-2015 How does the CFB boiler work CFB technology burns fuels without fire or burners in the furnace but through a process of fluidization mixes the fuel particles with limestone which captures the sulfur oxides that are formed and the low temperature reduces nitrogen oxide formation.

How Circulating Fluidized Bed Boilers Work?

Circulating fluidized bed combustors (or boilers) are one of the most widely used gas-solid convertors around the globe. As it plays an essential role in boiler design, different researchers have suggested different operating regimes for CFB combustors, based on their findings from experiments or practical experiences.

ANDRITZ to supply another highefficiency PowerFluid circulating

Circulating Fluidized Bed (CFB) boilers combine high-efficiency combustion with fuel flexibility. The technology can use local alternative renewable fuels like waste to produce cleaner energy and contribute to fossil fuel and CO2 emissions reduction.

Schematic of a circulating fluidized bed boiler Download Scientific

ANDRITZ PowerFluid boilers are based on Circulating Fluidized Bed (CFB) technology to produce steam and electricity from nearly all solid fuels from biomass to alternative fuels and wastes. PowerFluid boilers employ proven, yet modern combustion technology to efficiently produce power while keeping emissions within environmentally safe limits.

Crosssection of the circulating fluidized bed boiler. Download

Circulating Fluidized Bed Boilers: Design, Operation and Maintenance | SpringerLink Book © 2015 Circulating Fluidized Bed Boilers Design, Operation and Maintenance Home Book Authors: Prabir Basu Explains technologies and underlying scientific fundamentals Outlines practical applications in industry use

Circulating Fluidized Bed CFB Boiler Process YouTube

Drawing upon our extensive technical expertise and operating experience, B&W developed the Internal Recirculation Circulating Fluidized-Bed (IR-CFB) boiler which is the technology of choice for power plant owners seeking economy, reliability and flexibility.

Circulating fluidized bed boiler (cfb boiler) how does it work and it…

The circulating fluidized bed boiler (CFB boiler) is the second-generation fluidized bed boiler, the updated version of the bubbling fluidized bed boiler (BFB boiler).

Schematic illustration of a fluidized bed boiler. Download Scientific

Circulating fluidized bed (CFB) boilers use all kinds of solid fuels, from biomass to refuse derived fuel (RDF), to produce reliable and efficient clean energy. Fuel flexibility is at the core of CFB technology, contributing to fossil fuel and CO 2 emissions reduction while using local alternative renewable fuels.

CIRCULATING FLUIDIZED BED REACTOR Chemical Engineering World

It comprises three 150-MW units (Figure 1) that operate state-of-the-art circulating fluidized bed combustion (CFBC) boilers supplied by Hyundai Power Systems (HPS). HPS is a new name for the.

Schematic of circulating fluidized bed combustion (CFBC) unit. 29

A circulating fluidized bed (CFB) boiler is a type of fluidized bed combustion that utilizes a recirculating loop to increase an even greater amount of efficiency for combustion. The circulating fluidized bed boiler combustion uses all kinds of solid fuels, such as biomass and refuse-derived fuel (RDF) to produce clean and efficient energy.

Circulating Fluidized Bed Boilers at Best Price in Changsha, Hunan

Designed to stand the harshest conditions, CFB boilers can better resist tube corrosion, wear, and ash adhesion, making high-temperature, high-pressure steam conditions possible for all fuels. For large-scale plants, ultra-supercritical steam at 257 bar and 603°C is available. Fuel-flexibility is critical for new plants to maximize inexpensive.

LOW PRESSURE HYBRID CIRCULATING FLUIDIZED BED PT HAMADA BOILER INDO

Circulating fluidized beds (CFBs) are typically used for conducting moderate to fast heterogeneous catalytic reactions as well as combustion reactions. From:Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification, 2013 Related terms: Fluidized Bed Reactor Boiler Gasification Fluidization Pyrolysis Fluidized Bed

Professional 25T Circulating Fluidized Bed Boiler Good Heat Resistance

Junfu Lu Tsinghua University Hai Zhang Hairui Yang Tsinghua University Abstract Studies on circulating fluidized bed (CFB) boilers have being conducted at the Tsinghua University (TH) for.