Disused lift shaft in an abandoned coal mine — Stock Photo © PBphotos

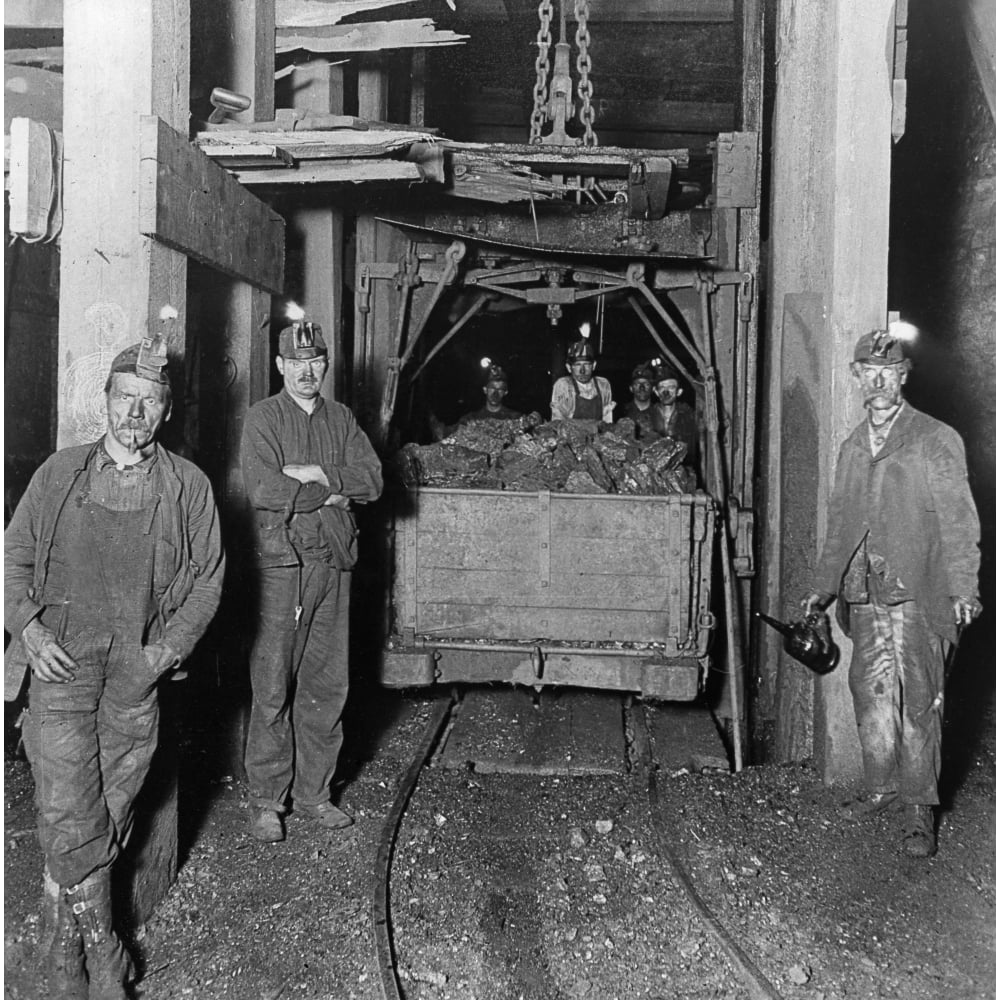

Underground mining is a difficult area for miners to work. Miners must go to the working faces by walking, which is not only time consuming but also physically demanding. In mines, a man-rider chair lift system (MRCL) has been developed to alleviate the strain stresses caused by walking lengthy and uneven distances up to the working faces. All parameters, including horizontal and vertical.

Pit and lift, miners, elevator Coal Mine museum, shaft, mineshaft

For instance, in 2019, Coal India, the main federal government-owned company that mines more than 80% of total coal in the country, paid approximately 500bn rupees ($6.7bn/£4.9bn) in taxes and.

Tower lift of a coal mine stock photo. Image of architecture 164640418

Mining methods Modern underground coal-mining methods can be classified into four distinct categories: room-and-pillar, longwall, shortwall, and thick-seam. Room-and-pillar mining In this method, a number of parallel entries are driven into the coal seam.

How Do MineShaft Elevators Work Some Interesting Facts

The Gevra coal mine, India's largest, aims to produce 52 million tonnes this year. Coal India plans to open two more mines with combined annual capacity of 7 million tonnes in the financial year.

Mine head headgear / lift cage winding wheels at the Louisa coal mine

. Analysis of Longwall Pillar Stability (ALPS) has been widely used in Australia and the USA for the design and optimization of chain pillars (Colwell et al. 2021;Mark 1987). This program works.

Coal India editorial stock image. Image of dirty, horizontal 33542039

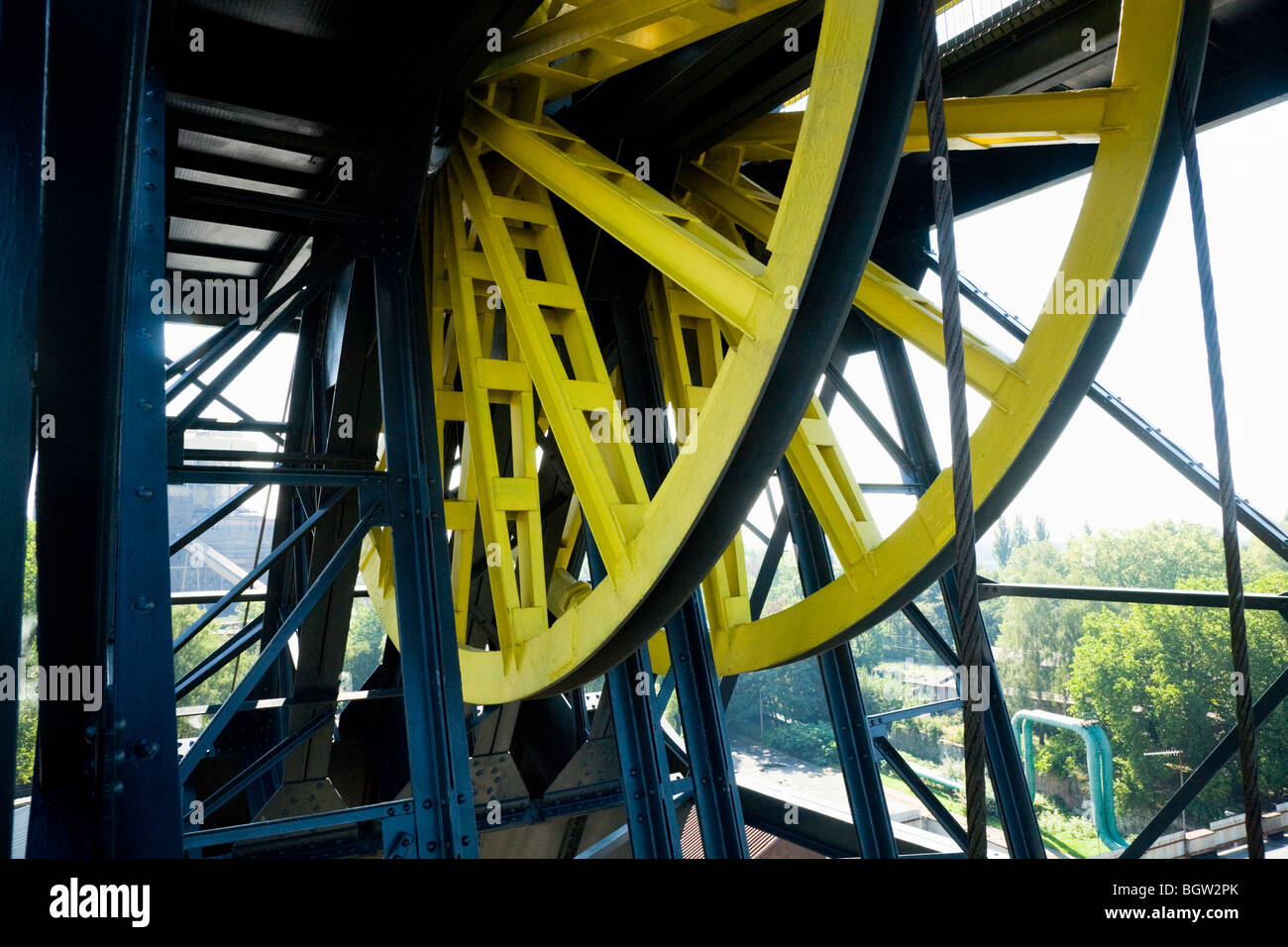

A headframe housing a friction hoist Friction (or Koepe) [3] hoists are the most common type of hoist used in Europe, Asia and Australia. [1] The friction hoist was invented in 1877 by Frederick Koepe. [4] Friction hoists are mounted on the ground above the mine shaft, or at the top of the headframe.

Pit and lift, miners, elevator Coal Mine museum, shaft, mineshaft Stock

THE MODERN WONGAWILLI METHOD. The Wongawilli system involves much larger blocks of up to 200 m wide. It consists of a 2 or 3 heading entry headings driven through the centre of the panels, splitting the panel into two smaller panels. The panel can be up to 1000 m long. Lifting of the fenders is carried out to the left and right of the split.

Mine head headgear / lift cage winding gear tower at the Louisa coal

Small coal at one time referred to charcoal, but this usage is obsolete. Snap or bait. Snap, bait or piece is food taken to eat part way through the shift and often carried in a snap tin. Sough. A sough is a drainage tunnel to take water from coal mines without the need to pump it to the surface. An example is the Great Haigh Sough. Spoil tip

Coal Mine Lifts Pictures Getty Images

ABB has the unique capability to design, supply, install and provide long-term service and support of entire mine hoist mechanical and electrical systems. We supply friction hoists as well as drum hoists of various types. We also supply the shaft equipment necessary for productive hoisting processes. ABB mine hoist solutions provide low life.

Training, Unique and Coal mining on Pinterest

Australia's 15 proposed coal mines would increase methane emissions by an estimated 190 thousand tonnes per year, adding one-fifth to the already hefty methane footprint of Australia's coal mines. Almost two-thirds of these additional emissions would be from thermal coal mines. On Thursday the federal government closed its first-ever.

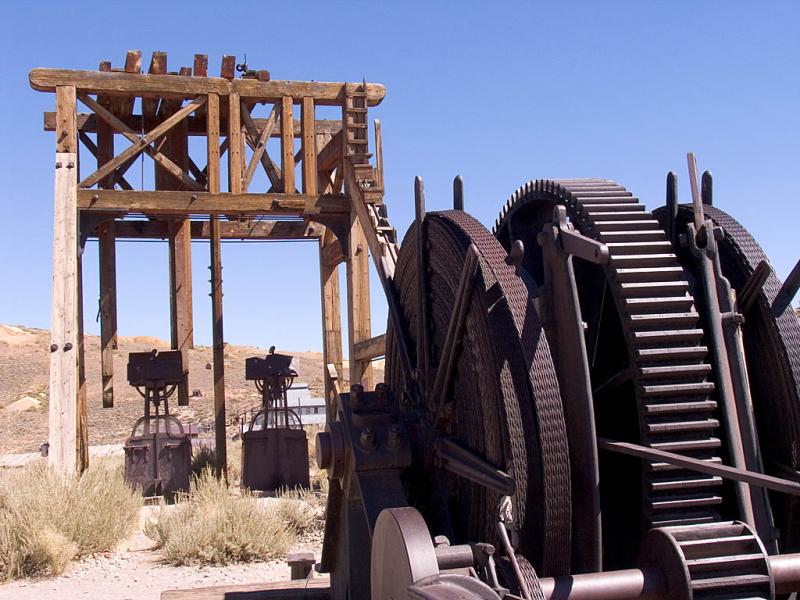

Free Images architecture, wheel, steel, transport, vehicle, tower

Coal mining, extraction of coal deposits from the surface of Earth from underground. Coal has been used since the Bronze Age, 3,000 to 4,000 years ago, and was the basic energy source that fueled the Industrial Revolution of the 18th and 19th centuries.. Crude methods were devised to lift it to the surface. A bucket-and-chain device was.

Pennsylvania Coal Miners. /Nminers And A Car Full Of Coal In An Coal

Despite Illinois' position as a national leader on climate and energy policy, coal mining is still an active industry in the Prairie State. In fact, Illinois is the fourth largest coal-producing state in the US. In 1930, Illinois produced 45,776,272 tons of coal. Nearly a century later in 2019, Illinois produced 45,408,293 tons of coal.

Coal Miners exit the mine shaft lift after a day's work in the... News

Auger - A rotary drill that uses a screw device to penetrate, break, and then transport the drilled material (coal). Auxiliary operations - All activities supportive of but not contributing directly to mining. Auxiliary ventilation - Portion of main ventilating current directed to face of dead end entry by means of an auxiliary fan and tubing.

The World’s Top 5 Biggest Mining Dump Trucks

Since 1937, Fletcher has been engineering and manufacturing custom solutions for underground mining. Today, Fletcher products expand into a variety of industries. Through the decades, Fletcher has operated with a singular vision: to work with a vigilant focus on finding ways to improve mining and industrial processes and reducing risk for the people who work in those industries.

Mine head headgear / lift cage winding gear tower at the Guido coal

A portion of this program was to be expended for the elimination of stream pollution from abandoned coal operations, air pollution from burning coal refuse banks, alleviation of subsidence from abandoned mining operations and elimination of underground mine fires.

Pit and lift, miners, elevator Coal Mine museum, shaft, mineshaft Stock

Nuttallburg became the second mining town in the New River gorge to ship the "smokeless" coal, processed from a mineral seam hundreds of feet above the river corridor and shipped to industrial cities hundreds of miles away.