Melt metal with Physics Science Experiment YouTube

Best Metal Melting Furnace 1. USA Cast Master GG 5000 SS (review) 2. TOAUTO 3kg 1400W (review) 3. FASTTOBUY 6kg (review) 4. Cast Masters GG 10-12kg (review) 5. CANALHOUT 6kg Kit (review) Jump To… Top 5 Metal Melting Furnaces Why Use a Metal Melting Furnace? Benefits Choosing the Right Furnace 1. Fuel Type 2. Capacity 3.

Melt metal tools with electric shock Experiment Crazy Transformator

The main advantage that attracted the attention of researchers was the lack of contact of liquid metal with refractory lining, which ensured the elimination of one of the main sources of metal contamination by such a harmful impurity, such as oxygen. This is especially important for melting refractory and highly reactive metals and semiconductors. Compared to other melting methods, which also.

Iron can melt, what happens when the melts? By HSMAG

Subsequently, the field of application of electro-magnetic pulse (EMP) was significantly expanded. The authors note that the metal melt was processed by PMF with the parameters 75hI·A and 6kI·Hz (here hI and kI, which describe the characteristics of the machine, are the coefficients of the pulse generator and remain constant). The ingot.

How to Melt Metals (Beginners Guide) YouTube

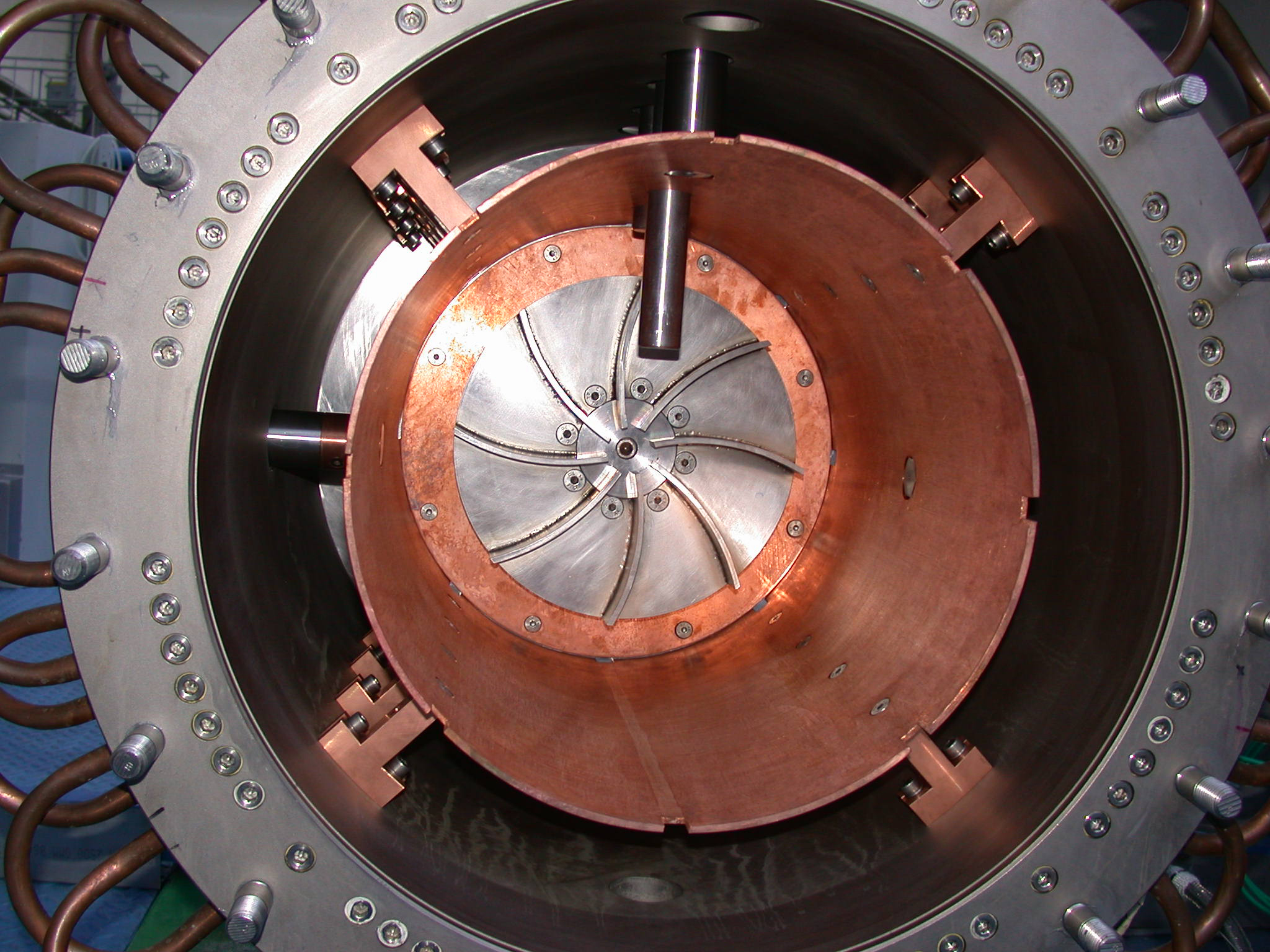

A high magnet flux density was observed in the melt near the electromagnet to which a strong current input. The case 3 condition shows larger magnetic flux density than the cases 1 and 2 due to the activated 6-pole electromagnets.. The distribution of the magnetic volume force formed in the molten metal, which is the source force of melt.

Melting Metal

Abstract The necessity of studying the stirring of liquid-metal components to form homogeneous alloys is substantiated. A mathematical model is developed for the electromagnetic stirring of alloys produced in an electric arc furnace. A special-purpose experiment is carried out to test the proposed model. The results of calculations and experiments performed on a small electric arc furnace are.

47. Melting point, Bond dissociation energy, and Bond energy

The purpose of this review is to: (i) give an overview of the main EPMs used in the manufacture of bulk ceramic or metals components; and (ii) to generalize physical effects (field/current effects on matter) within EPMs.

A Step By Step Guide on How to Melt Metal

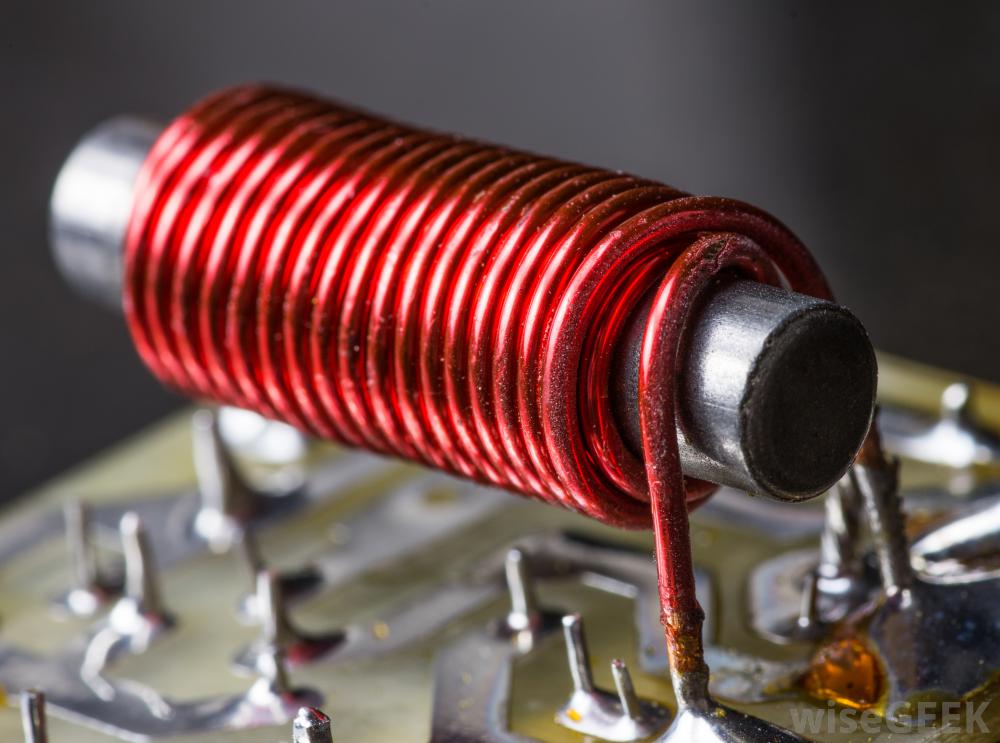

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an inductor that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide.

17 Metals With the Highest Melting Points (and Why) Materials Science

The Electromagnetic-Levitator (EML) on the ISS is discussed and possible designs for future EMLs are presented. Further, the possible applications of metal as a potential source of propellant for electric propulsion systems and as feedstock for in-space manufacturing are discussed.

Melting Metal with Induction

1. Electric furnaces are offered with holding capacities from 1,200 to 20,000 lbs. These metal capacities allow for maximum drawdown prior to recharging. 2. The furnace is capable of "melting back down" if a metal freeze-up occurs due to extended power failure. The time frame of the re-melt depends on metal temperature and holding capacity.

Melting Points of Different Metals

The electromagnetic levitator ISS-EML on the International Space Station (ISS) offers perfect conditions for such experiments. This way, data for process simulations is obtained, and a deeper.

Many Moving Melting Metal YouTube

The copper wire has a significant amount of AC electricity running through it, causing it to act like a really strong electromagnet. In the metal slug, eddy.

Physics Molten Metal

The billet heating technique by rotating conductive material in a magnetic field for aluminum extrusion has been reported, but metal melting technology by the induction heating with the dc magnetic field has not. Further complex geometries of aluminum profiles are formed by the casting that requires highly efficient metal melting technology. In order to verify the capability of induction.

What Makes a Stick? The Science Behind

1 Altmetric Explore all metrics Abstract Heating plays a vital role in various manufacturing processes of metallic products. Microwave heating has many advantages over conventional conductive heating methods while it is currently limited to heating dielectric materials and powdered metals.

Flexitune Levitation Melting YouTube

84 Comments by: Brian Benchoff April 8, 2012 built by [bwang] over on Instructables. It gets hot enough to melt and forge steel, iron, and aluminum. this induction heater from a few years ago. A.

levitation melting of aluminium (MHD simulation) YouTube

The Electric Metal Makers Guild is an international organization of electric melting furnace operators. The purpose of the Guild is to promote the development, manufacture, and use of metals produced, refined, or treated, wholly or partially, in electric melting furnaces. Its mission is to assist the metal melting industries through the.

melt metal with field, Electronic and

Smelting is the process of removing a metal element from mined ores. Most metals are found as veins in rocks, or as parts of other elements. Smelting is the first step of extraction. Melting is what is done with metal alloys or pure metals. Scrap is melted, ore is smelted. Pig iron is the rough iron ingots created from iron ore smelting.